CHEMICALS AND PETROCHEMICALS

CHEMICALS AND PETROCHEMICALS

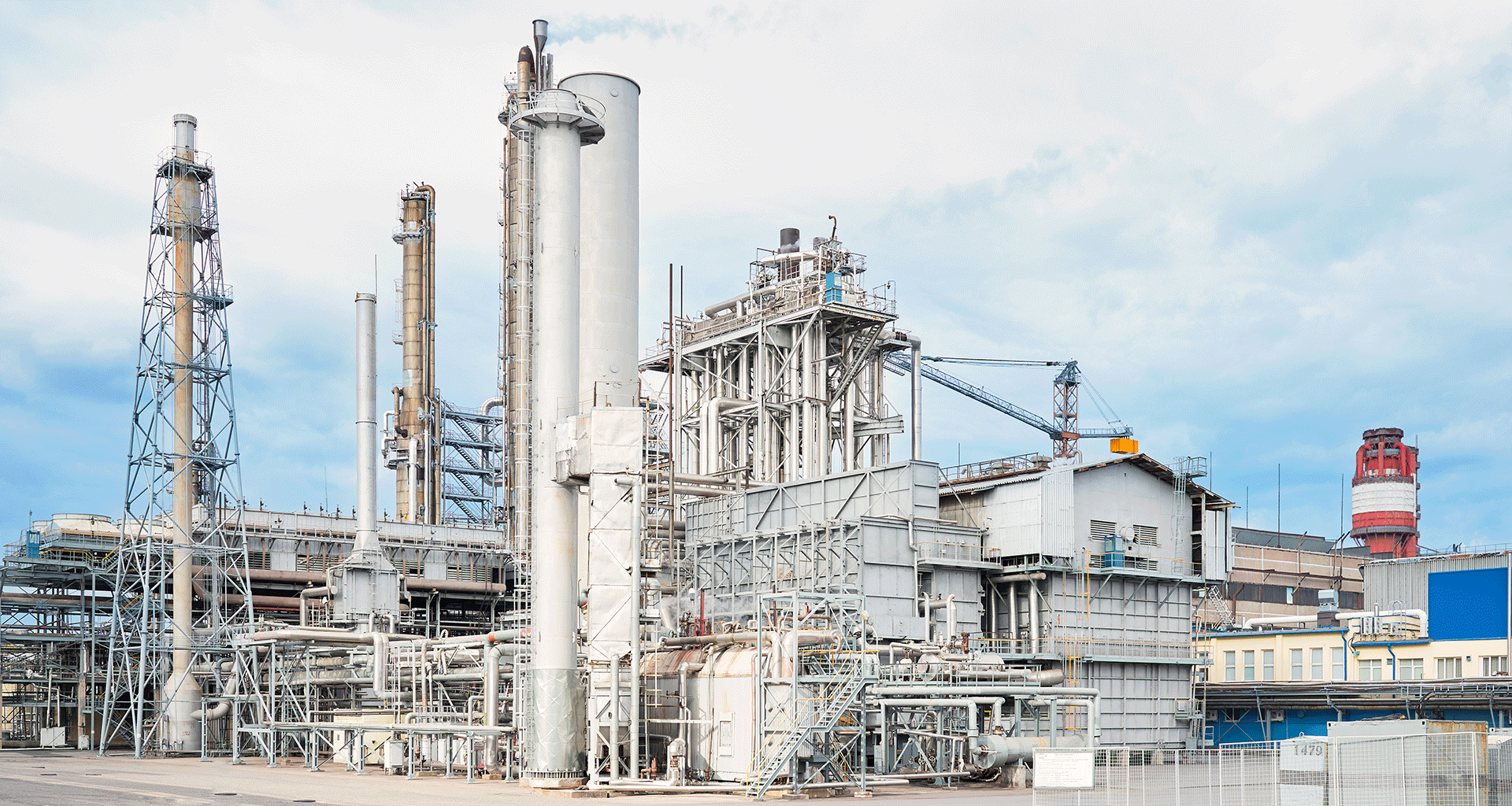

The Chemical and Petrochemicals business manufactures and sells a wide range of consumer and industrial goods. Every consumer or industrial product has a chemical link, and for the majority of them, petrochemicals are at the heart of them. They serve as the foundation of numerous industries, including cosmetics, textiles, packaging, toiletries, electronics, automobiles, paints, and so on, and they are also critical to global energy consumption. Petrochemicals are made from hydrocarbon-based substances such as crude oil, coal, wood charcoal, and, in certain circumstances, biomass.

Petrochemicals are divided into two groups: olefins (ethylene, propylene, and butadiene) and aromatics (benzene, toluene, and xylenes), and they serve as the foundation for a variety of valuable goods. They also manufacture a class of compounds known as hydrocarbon intermediates, which are much more sophisticated copies of their basic counterparts.

Our team at Prozemek Solutions is a specialist in petrochemical and chemical plant engineering services, with hands-on expertise in building and commissioning Open-art or Licensed Plants, Polymerization Plants, Solvents Recovery Plants, Fluorine Chemistry Plants, Chlorine Chemistry Plants, Continuous and Batch Process Plants. We analyze the existing systems and create new designs to increase production capacity. We also design utility systems that are required for the operation of process units, as well as load, unload, and storage solutions for raw materials and completed products.

Specialized Packages

The interaction of nitrogen and hydrogen in high-pressure converters produces ammonia. Much of the chemical

generated is utilized in fertilizers in form of ammonium sulfate, ammonium nitrate, and anhydrous liquid.

Liquified petroleum gas, Natural gas, or petroleum naphtha are first converted into gaseous hydrogen in a typical

contemporary ammonia-producing facility. The hydrogen is subsequently mixed with nitrogen in the Haber-Bosch process

to make ammonia.

We are well-known for our plants that produce Caustic Soda, Chlorine, and Chlorine derivatives. One of the most

significant chemical feedstocks is caustic soda (NaOH). NaOH is used in the manufacturing of aluminum, the paper

industry, the food processing sector, the creation of detergents, and so on. Caustic soda is a by-product of chlorine

manufacturing, which is done 97 percent through the electrolysis of sodium chloride.

PSPL's sulfuric acid plant solutions can help you improve operating efficiency, sustainability, and safety. Our technology

is built on years of expertise in a wide range of tasks. We also provide a broad selection of service options to help you

throughout the lifespan of your plant. Our primary focus is on safety and dependability. Our ideas incorporate a distinctive

design of core sulfuric acid equipment, the utilization of energy-efficient, low-emission technology, and the use of as little

water as possible. We provide solutions for a wide range of production requirements, from modular choices to low-capacity plants

to mega-capacity facilities.

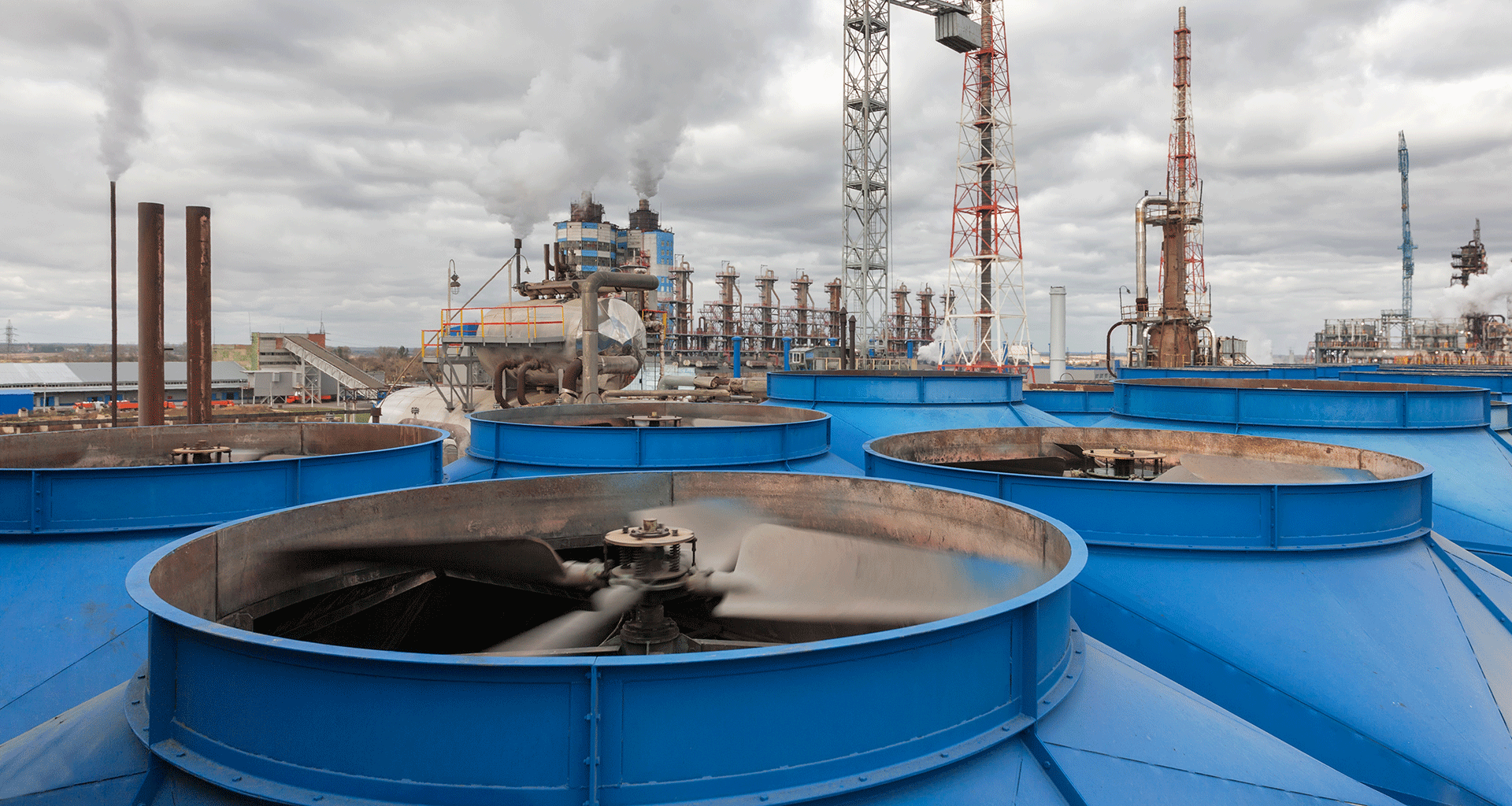

A refrigeration plant is made up of several components, each of which serves a specific purpose. This plant's operation is based on

vapor compression refrigeration technology. The flooded type evaporator, reciprocating compressor, evaporative condenser, metering

devices, and receiver comprise this vapor compression refrigeration system. This refrigeration plant also includes an oil separator,

a non-condensable gas purger, and a liquid separator.